AI & Machine Learning Solutions in Melbourne

We automate business processes, deliver insights, and help create a true competitive advantage using smart AI & Machine Learning solutions.

We automate business processes, deliver insights, and help create a true competitive advantage using smart AI & Machine Learning solutions.

Alliance Software utilises a broad range of cutting edge technologies including AI & ML as part of our mobile application and software development services.

We can add real time predictive power to your platform or technology, enabling your business to gain insights & a genuine competitive edge.

We specialise in Predictive Analytics, Machine Learning, Deep Learning, Data Mining, Business Intelligence (BI), Image Processing and a range of related AI / ML services.

We're your local machine learning company.

Whether you're building core business technology with well-defined requirements, or learning as you take a new idea to market, we can deliver the best solutions in personalised software.

Does your business have access to a wide variety of key business data, but fail to make effective use of it?

By applying the latest in Machine Learning we can help you predict key customer behaviour, including future purchases and churn.

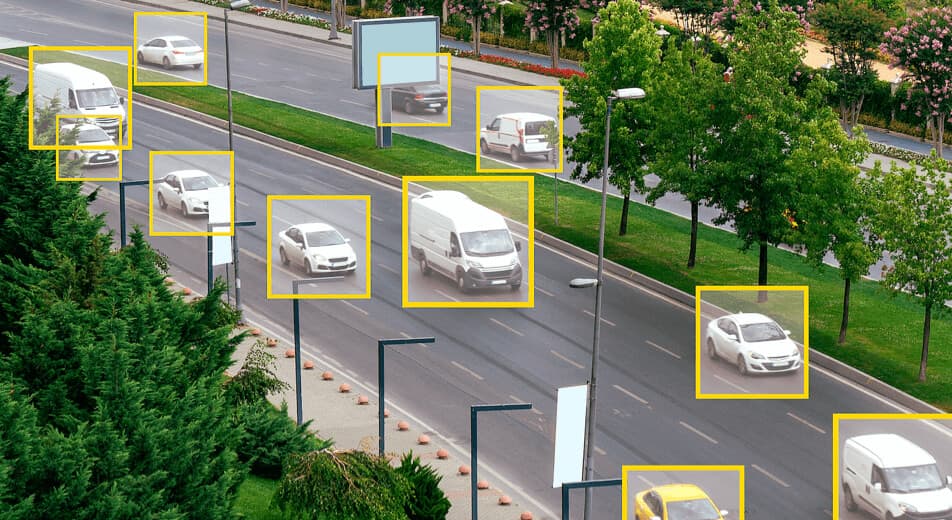

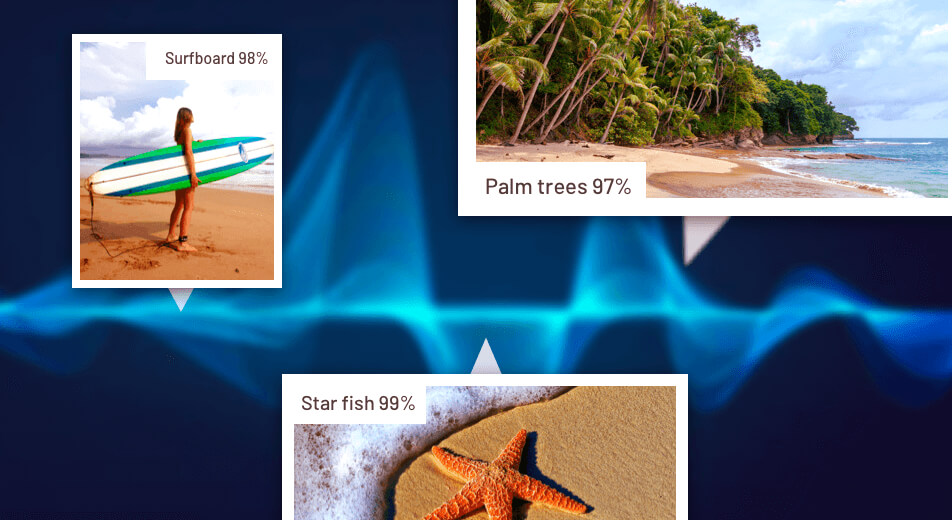

Do you capture photographic, audio or video footage? Would you like to be able to make accurate, real time predictions with this data?

Our data scientists have successfully developed predictive models for a variety of image analysis applications.

Deep Learning is a more advanced and automated form of Machine Learning. Let us show you how to use Deep Learning to build powerful supervised or unsupervised models to help increase operational speed, reduce errors and automate your processes.

Our highest priority is helping you achieve your business outcomes, so we'll happily deploy either custom-built artificial intelligence solutions or use off-the-shelf solutions from Google, Amazon, Microsoft or others.

AI and ML are tools that can be targeted to solve specific business problems. Here are just a few of the areas where these tools can be applied to business today.

Improve purchase volume and frequency with a recommendation engine tailored to your business. Grow revenue with intelligent optimisation of your advertising.

Detect anomalies and fraudulent transactions in large data sets. Use facial and object recognition in image and video to identify intruders.

Use intelligent demand prediction to optimise staffing and physical asset allocation. Maximise inventory turns whilst reducing stock shortages with machine based sales projections.

Protect your profits and reduce customer churn by predicting, in advance, those customers most likely to leave you.

Detect manufacturing defects in real time. Assist knowledge workers with context sensitive recommendations, text analysis and document categorisation at scale.

Use intelligent support agents, in concert with human support staff, to create a high quality and scalable customer support function.

Find out how you can apply the latest in Machine Learning and AI to your business problems today. You'll understand timeframes, data requirements and importantly, how to confirm viability early in the project.

Let's have a quick 15 minute chat to find out.

Get in touch

The outcome. A product that came in below budget, on time, has a 92% Net Promoter Score and is growing 10% month on month. A considerable amount of this success can be attributed to Alliance.

We've created automated tools to analyse recent real estate sales and predict likely rental yields.

Our video creation platform allows users to upload custom audio and slides and performs the timing synchronisation automatically.

Identifying room types from photographs and synchronising with the written content in real estate listings to automatically generate sales videos.

We've built algorithms to highlight the key objects in any photograph and, where a caption such as “the boy walked onto the green school bus” exists, identify the named objects in a sentence.

We've developed algorithms to monitor time-delay photographs and identify a range of wildlife based on the photo stream.

Implementing a quality software solution starts with a chat. Call us on 03 9955 7000 or leave your details and we’ll be in contact shortly.

We won’t share your information with anyone.